خلاصہ

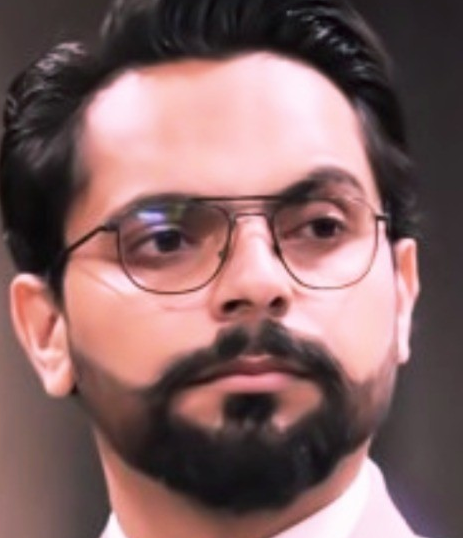

An initiative-driven and seasoned engineering professional with 13 years of success in infusing efficiency into the operations and maintenance, from policy formulation and implementation to the ideation and development of operations and processes to performing the functions of supervising, planning, training, development of teams.

Currently, I serve as an Operations and Maintenance Manager, overseeing operations and ensuring optimal performance.

In my previous roles within food and beverages manufacturing companies, I excelled in maintenance management, leading shifts and collaborating with teams. I am proficient in maintenance management and scheduling, ensuring minimal downtime and maximizing equipment efficiency.

My expertise extends to maintenance documentation and utilizing CMMS tools to streamline processes. Additionally, I successfully implemented 5S methodology in spare parts stores, resulting in the clearance of 5 million Saudi riyals worth of dead inventory.

With a strong technical background, I have received extensive training in Total Productive Maintenance, advanced maintenance techniques, and instrumentation and control processes. This knowledge has allowed me to develop innovative solutions and optimize operations for clients from various industries during my tenure in technical sales and projects.

I am passionate about driving continuous improvement, increasing operational efficiency, and achieving tangible results. If you are seeking a dedicated Mechatronics and Control Engineer with a proven track record in operations and maintenance management, let's connect and explore opportunities to collaborate.

تجربہ

Manager Operations & Maintenance

• Oversee and manage the day-to-day operations, ensuring smooth production

processes, on-time delivery, and adherence to quality standards.

• Communicating regularly with senior management on production and

maintenance performance and results.

• Lead a team of maintenance technicians and operators, providing guidance,

training, and performance evaluations to ensure a skilled and motivated

workforce.

• Create and maintain preventive maintenance schedules for equipment and

facilities to minimize downtime and maximize equipment lifespan.

• Conduct regular inspections and audits of equipment, machinery, and facilities

to identify maintenance needs, troubleshoot problems, and ensure compliance

with safety and quality regulations.

• Collaborate with procurement and vendor management teams to source and

negotiate contracts with external suppliers and service providers, ensuring timely

delivery of goods and services.

• Maintain accurate records and documentation of maintenance activities,

equipment performance, and operational metrics, preparing reports and

presentations for management review.

• Identify opportunities for process improvement, cost reduction, and productivity

enhancement. Lead initiatives such as Lean manufacturing, Six Sigma, or other

improvement methodologies to drive operational excellence.

• Ensuring compliance with safety and environmental regulations.

Senior Business Development Engineer

• Analyze existing and potential markets to identify and secure business development opportunities.

• Assist marketing team in preparing market plans and strategies to promote company’s products.

• Researching organizations and individuals online (especially on social media) to identify new leads and potential new markets

• Lead marketing campaigns, trade shows, technical seminar etc. in order to increase company’s recognition.

• Prepare effective proposals, presentations, demonstrations and sales tool on business development opportunities for management.

• Develop good customer relationship by personal visits, phone calls, follow-ups, e-mails etc.

• Maintain strong relationship with customers for future business growth.

• Assist purchasing team in quotations activities like price and delivery negotiations with customers.

• Offering after-sales support services. • Preparing reports for head office and senior managers.

• Through negotiations, project support, and product consulting, form a partnership with clients resulting in a key endorsement of the company product and a mutually beneficial business relationship. Projects Completed:

• Assisted in erection and commissioning of Uzermak cheese processing CCM-90 and CS-200 machines.

• Supervised all arrangements and successful execution of exhibition at IFTECH 2018. • Supervised all arrangements of Seminar of Alfa Laval, conducted at PC hotel Lahore.

Assistant Manager (O&M)

• Identify, diagnose and resolve operational, manufacturing and maintenance problems

within deadlines.

• Interpret and develop reports including standard operating procedures.

• Developing and maintaining safety standards.

• To conduct machine setup, troubleshooting, corrective and preventive maintenance

services.

• Perform root cause analysis and resolve problems

• Manage, coach and develop a high performing Maintenance team that meets agreed

objectives and which delivers best practice results, added value and continuous

improvements.

(Assistant Manager (O&M))

• Worked as Assistant Manager (O&M).

• Managed and supervised the daily operations.

• Identify, diagnose and resolve operational, manufacturing and maintenance problems within deadlines.

• Establish the budget concerning all aspects of Maintenance & Repair of the Manufacturing department and guarantee it’s cost-effective use and compliance.

• Ensure high customer satisfaction ratings, maintain production goals and reduce inventory carrying costs.

• To conduct machine setup, troubleshooting, corrective and preventive maintenance services.

• To facilitate and co-ordinate all reactive (breakdowns) works and set priorities of works in shift.

• Manage, coach and develop a high performing Maintenance team that meets agreed objectives and which delivers best practice results, added value and continuous improvements.

Projects Completed:

• Initiated and implemented Planned Maintenance practice on Tortilla production Line.

• Participated in erection of Tetra Pak production line.

Technical Expertise:

• Familiar with mechanical manufacturing and design process.

• Played lead role in the project initiation stage to the actual execution stage.

• Develop new procedures and processes to improve production accuracy.

Maintenance Engineer

• Worked in Maintenance Department as Maintenance Engineer.

• Hands on experience of maintenance of Ocme, Sidel, Sacmi, Meypack, Arol, Alsim, Ads, and Robopac.

• Periodically measure and analyse wrench time & work with maintenance team to effectively utilise shift resources, provide implementation of Preventive works.

• Assisted the Maintenance Manager in planning maintenance budget.

• Assisted the Stores Manager in spares parts section.

Assignments Completed:

• Initiated and implemented Planned Maintenance practice.

• Erected and Commissioned 72000 B.p.h Sidel Filling Lines.

• Erected and Commissioned 78200 B.p.h Sidel Filling Lines.

• Commissioned 6000 B.p.h Sipa Filling Line.

• Assisted in Machines spare parts categorization and inventory Control project

TECHNICAL EXPERTISE

• Overhauling of SIDEL PET Filling Lines during Annual Turnaround.

• Overhauling of SIPA PET Filling Line Annual Turnaround.

• Annual Turnaround planning, preparation and execution.

• Inventory Management

• Project Management.

Shift Engineer

• Preparation & Implementation of Daily Maintenance Schedule (DMS)

• Long and short term management of Man, Materials and Machinery

• Budget Proposals and preparation for spares, general store items

• Minimizing breakdowns, designing progressive plans

• Preventive, predictive and breakdown maintenance of plant’s equipment

• Indenting and technical evaluation for procurements for the above mentioned items

• Assisted annual maintenance with Technical Operations Manager at PET bottle lines

• Look after the operations and maintenance of utility equipment (compressors, chillers, cooling towers)

Assignments Completed:

• Implementation of Maintenance Planning Software (EAM) at the production plant level.

• Initiated to conduct Annual Maintenances through EAM software.

TECHNICAL EXPERTISE

• Overhauling of KHS PET Bottling Lines at Riaz Bottlers during Annual Turnaround 2009 and 2010.

• Overhauling of Ateliers François and SIAD Air Compressors at Pet Lines.

• Annual Turnaround planning, preparation and execution.

• Inventory Management