概要

Track record of achieving sustained improvements in quality, cost, and delivery functions in manufacturing and Production domain

I am a results-oriented Plant Manager with extensive experience within the production and manufacturing field. Instrumental in planning production schedules over multiple shifts and streamlining production processes, while operating in a time-constrained environment. Experienced in managing Production, HR, Quality, Safety, logistics and Cost Control for fortune 500 companies Kraft Foods USA, Kroger Manufacturing (Plastic molding & injection - Beverage & Drinks) USA, DeLaval Mfg. USA (Dairy Form & Cleaning Solutions), Whitmore Mfg. (Lubricants), Fritz Industries (Petroleum Chemicals), Mother Parkers Tea & Coffee manufacturing. Drive success in achieving accuracy and problem solving utilizing lean manufacturing procedures to reduce costs. Ability to design and enhance processes in support of continuous improvement programs.

I am a resourceful leader directing teams to peak performance, build and maintain strong relationships at all professional levels, develop and create various quality products to achieve production goals. Six Sigma Green Belt, 40 hours OSHA General Safety Certified, 40 hrs. Ergonomics training, Kaizen method to resolve issues, OEE in charge, HACCP (Hazard Analysis Critical Control Points), LOTO, and First Aid/CPR certified, Visual Management techniques and extensive training in managerial and Quality work audit experience, enthusiastic and self-motivated. Developed SOPs and Work Instruction for different projects. Demonstrated track record in training, mentoring and motivating teams to improve overall productivity and performance. Managed various root cause failure analysis investigations in response to safety and equipment failures.

Design and enhance processes in support of continuous improvement programs.

QCMS (Quality Chain Management System) audits, OEE (Overall Equipment Effectiveness), Industrial Work Ergonomics Training, Kaizen Methodology, HACCP (Hazard Analysis Critical Control Points), LOTO (Lockout Tagout), Confined Space trained, CIP (Cleaning in Place) & COP (Cleaning in Place) trained, First Aid/CPR certified, AEDs (Automated external defibrillator) trained, OSHA General Safety 30 hrs, Work Ergonomics 40 hrs. Training, Visual Management techniques, QCDSM (Quality, Cost, Delivery, Safety and moral), 5s Implementation, 6 sigma Lean manufacturing, Waste Management, TQM (Total Quality Management), Emergency Preparedness and Response. Fire extinguisher trainer, JIT (Just in Time), TPM (Total Productive Maintenance), QC tools, SAP (systems, applications, and products) & JP Edwards

My key skills include Industrial Operations Management, Lean Six Sigma Manufacturing, Equipment Maintenance, Visual Management Techniques, Industrial Work Safety, Work Ergonomics, Quality Assurance, Logistics, Expert in GMP’s, 5S, SOPs, ADP, PPEs, and HACCP (Hazard Analysis Critical Control Points) Plans, Lead teams to Improve, Quality Safety Procedures & Policies, Maximize Production, Reducing Product Waste by Recycling, Achieving above Target Goals

Technical Skills: ADP, SOPs, PPEs, SAP, JD Edwards, OEE, MS Excel, Word, Access, Outlook, & PowerPoint

My professional background and great industrial exposure coupled with an excellent track record makes me an ideal candidate for executive roles. As such I would welcome a discussion regarding opportunities with your organization that fit my background.

项目

工作经历

Plant Manager

Managed entire plant activities related to production, Quality, Safety, Delivery (Shipping, & receiving) handling employees\' HR issues, and their job performance reviews as well.

Reported to City of Grand Prairie & State of Texas: Semi & Annual Environmental compliance reports, Wastewater PH in range discharge, Pollution prevention Solid waste reports, annual pre-treatment status report.

Managed City and State violations in consultation with 3rd party environmental Company; conducted Mineral Acid Testing in compliance with environmental regulations to the City of Grand Prairie.

Managed the March 2019 City of Grand Prairie inspection & FDA (Federal Drug Administration) audit, also implemented FDA recommendations and monitoring process improvements.

Achieved overall Business decisions & implementation of Capital projects at Grand Prairie Plant i.e. Capacity increase, Daily production Liter/Man Hour, and improving work safety by introducing safety programs.

Assigned improvement projects, enforcing labor usage, ensuring employees and plant safety was a top priority.

Installed two capital projects of new production mixer tanks 10,000 lbs. & 6000 lbs. Ensured purchase, design, and validation USD 80K. Successfully purchased two new storage tanks, soliciting re-coating containment area, electrical work, and plumbing USD 92K., also acquired and installation of a new agitator from Sweden.

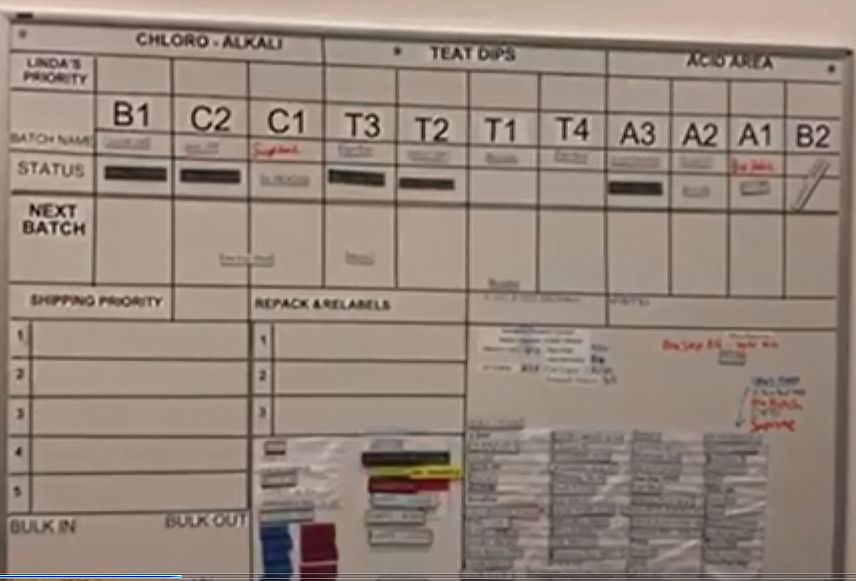

Rolled out 5s, floors marking and paint/stripe, maintenance shop; revised 5s program to de-clutter the floor, initiated Production Communication Board to cover Daily Production, Safety, Quality, and environment reporting.

Managed all HR responsibilities i.e. hiring new employees, on-boarding, and Safety training as well as conducting yearly reviews. Managed entire chemical plant operation in Dallas Texas

Performed employees\' reviews and yearly compensation based on their job performance. Implemented Kaizen & 6 Sigma lean manufacturing program to improve productivity and reduce waste.

Production Supervisor

Tasked to manage the Plastic Moulding Machine and Injection unit production & maintenance to produce 1K bottles per minute. Scheduled and cross-trained productive employees for the best results.

Exercised hands-on approach and effective controls to schedule maintenance and quick change over crew on packaging machine for different sizes. Reduced downtime and achieved better results.

Challenged with the responsibility to manage 60 employees\' Production and processing schedules, also built a team to achieve desired results and maximize company productivity.

Defined daily goals of syrup room and for achieving daily goals, achieved weekly production demand, and made sure completion of proper documentation and internal audits were conducted.

Led daily manufacturing issues and resolve them on a priority basis. My responsibility also included managing the maintenance crew for the water bottle filling machine on a priority basis to reduce any downtime.

Scheduled preventative maintenance on plastic molding and injection machines for the production lines.

Devised daily safety training and Kaizen boardwalks and to have clear communication throughout the organization.

Managed and supervised production change-overs & implementation of the sanitation process following a matrix to avoid cross-contamination between the products.

Earned a company award for correct syrup formulation and quality testing approval, also defined all the employees\' corrective actions, accidents investigation reports, and yearly reviews.

Production Supervisor

Produced high-performance lubricants, friction modifiers, rail lubrication, coatings, and sealants to meet customers by following all quality specifications.

Assigned production compounders team and fillers ensuring safety, quality, and daily goals; used J. D. Edwards, software for daily inventory, labor costs, fill reports, and closing out the batch tickets for daily productions.

Adhered to OSHA & GMP guidelines and monitored team performance to meet the quality of the product and the safety of the employees. Set compounders loaded correct formulation onto EBT (Electronic Batch Transfers - computer program) when compounding different products.

Rolled out the 5S Program in Shipping and receiving for creating and maintaining a clean, organized, and high-performance floor that looks presentable.

Production Supervisor

Utilized acute technical knowledge and industry experience to prepare employees\' schedules for daily & weekly batch production. Successfully launched 5s program to bring order to the floor and remove the clutter.

Designated areas for the employees for daily sanitation and cleaning of the equipment. To eliminate, reduce and rework products by enforcing quality work and SOP & formula implementation.

Successfully implement HR policies to discipline associates to establish a quality work environment.

Introduced audits for quality documentation to eliminate errors. Addressed and sustained correct documentation procedures to ensure traceability and good manufacturing practices (GMPs).

Followed OSHA regulations & Fritz Industries GMP guidelines and monitor team performance to meet quality and safety on daily basis.

Organize safety training for the employees to stay up to date. Reported monthly production reports to the top management and shared production growth performance.

Boosted employee morale for best job performance and turned underperforming by corrective action program.

Production Supervisor

Managed daily production and processing of up to 60+ employees. Followed and implement OSHA, HACCP and Kraft foods Company policy to achieve the best daily production results.

Exceeded Equipment effectiveness by 22%, improving Preventive maintenance and on-time parts delivery.

Scheduled 4 press, producing 6000 lbs. pasta every hour and achieved 17%, record production improvement by making the right decisions, and avoided production downtime.

Improved safety awareness by conducting monthly safety training and work ergonomics training. Conducted QCMS (Quality Chain Management System) audits to improve quality documentation and traceability.

Successfully designed a production line layout running specialty items. Worked closely with R&D to assist in developing new products and rollout processes.

Successfully achieved (SQF) Safe Quality food program to produce Quality food right for the first time.

Ensured products met all identified tolerances and specifications and improve targets by 13% demand by removing bottlenecks applying Lean manufacturing techniques.

Deliver and maximize production uptime. Implement GMP’s, SOP, and HACCP plans. Lead teams to improve Quality, maximize production, reduce product waste by recycling, and achieve above target goals.

Acknowledge hard-working employees with rewards and hold underperformers with corrective actions to achieve higher targets. Investigated accidents and quality issues and made corrective actions to avoid reoccurrences.

Strictly followed work safety rules and conducted JPHS (Job Process Hazard Analysis) training to improve safety. Roll out 6 Sigma Lean manufacturing to improved production and reduce downtime.