Summary

09+ Years of Experience in Mechanical

Maintenance.

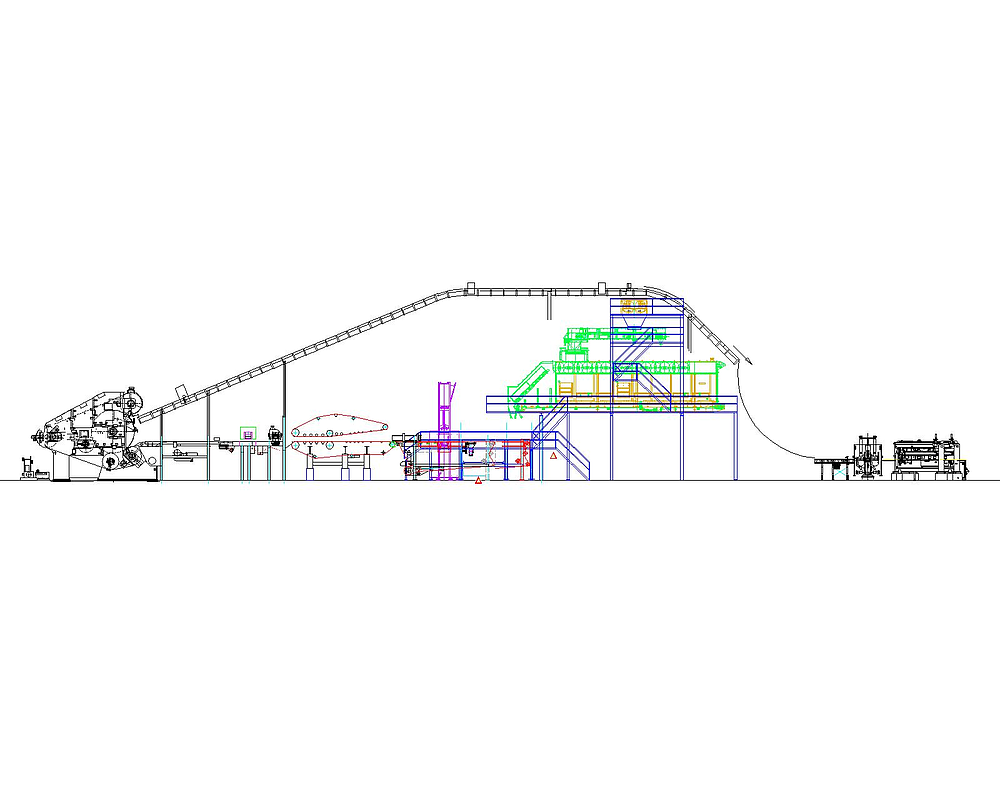

- One Project execution Experience (220Cubic Meter Medium Density Fiber Board production Plant) - wood Industry.

- Energy ( Steam generation, heat transfer oil & hot gases) Plant operational & Maintenance experience.

- Condition Monitoring of equipment.

- Implementation of preventive Maintenance.

- Planning & execution of Annual shutdowns for 03 Production plants.

- Rotary equipments maintenance experience. ( Pumps, industrial fans, blowers).

- Wood industry Process equipments upkeep & Maintenance experience. ( Drum chippers Refiners, plug screw feeders & Hot press).

- Utility Experience ( Firefighting piping repairs, utility piping repair).

- Different types of conveyor maintenance.

- Mechanical & fabrication Workshops operation.

- Managing fabrication works.

- Continuous process improvement.

- Training of staff & standardizing of maintenance practices.

- Managing spares (local, imported & manufacturing items).

- Liaison with vendors to improve equipment life & performance.

- Performing root causes failure analysis for repeated breakdown.

- Striving to achieve KPIs set by Management.

Projects

Experience

Deputy Manager Mechanical Maintenance

Managing the Maintenance Department

Assistant Manager Mechanical Maintenance

Working as head of Department

Senior Mechanical Engineer

Maintenance Engineer

Mechanical Engineer

Maintenance Engineer

Trainee Mechanical Engineer

-Erection & commissioning experience of 220 m^3MDF Board Plant as Project Execution Engineer

-Erection of new machines & modified second hand machines.

-Erection of Thermal oil pumping unit & its piping for Hot Press (19.2 G.cal/hr with ∆T 35°C)

-Erection & Fabrication of Ducts, cyclones, Bag filter systems, steel structures & piping.

-Layout designing through AutoCAD & installation of machines & parts as per drawing.

-Erection of Building Shed (Area Sq Ft 8504)

-Erection of Hydrlic units & its operation

-Making scheduled checks on machineries, parts and equipment and performing Preventive and Predictive Maintenance.

-Maintain reorder point of each machiney and its related accessories.

-Maintaining the inventory of local & imported items required for New Plant

-SOPs for Plant machines & equipments.

-Planning and execution of Planned Monthly and Annual Plant Maintenance.

-To perform technical analysis and enhance the production and quality by adopting modification work on different plant machineries.

-Managing unplanned work resulting from breakdown and emergencies, in a positive and efficient manner.

-Performing technical parameters of critical machines.

-Maintenance of rotary & stationary machines like drum chippers, centrifugal pumps, blowers & centrifugal fans & cooling towers, belt conveyors, chain conveyors & bucket elevators.

-Operation of Boge compressors S-60-2 ,S-125 & S-150-3

-Maintenance of MDF (Medium Density Fiber) board Plant special machines, Refiner L-36, Refiner L-42, Day Light -Opening Hot Press & Mende Auma Hot Press

-Maintenance of different types of Belt conveyors, Roller conveyors, chain conveyors & bucket elevator.

-Operation & maintenance experience of Reverse osmosis plant (25m^3).

-Operation & maintenance experience of Energy plant (25Gcal/hr capacity) for thermal oil heating & steam generation.

Managing team of 50 memebers, including general staff, shifts staff, workshop and fabrication team.