خلاصہ

I am a passionate engineering manager with more than 6 years of experience in electrical engineering including process control system, industrial automation, power and distribution system, energy audits and project management in multiple dynamic organizations with the knowledge of all engineering codes and standards.

پراجیکٹس

تجربہ

Engineering Manager

Key responsibilities:

Electrical System Management:

Manage maintenance, repair, and calibration of electrical equipment/systems.

Develop preventive maintenance schedules for reliability.

Automation and Control Systems:

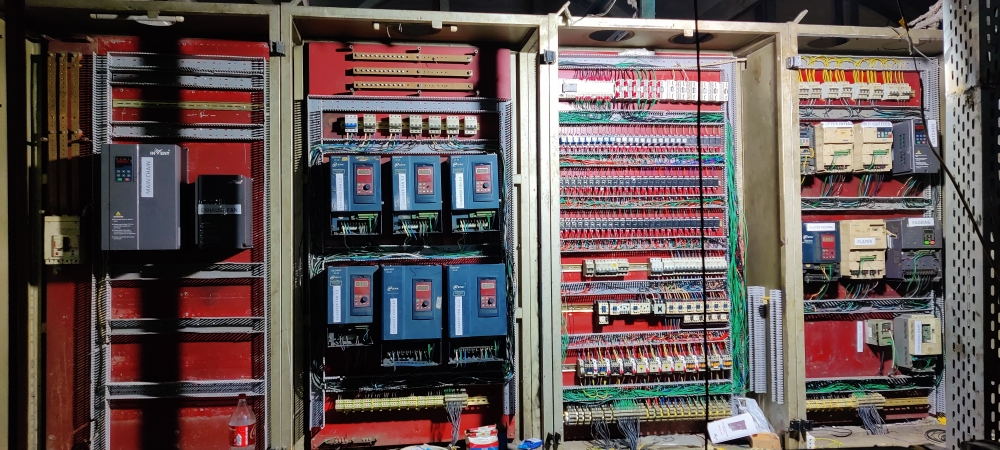

Oversee design, implementation, and maintenance of (PLCs), (DCS), and (HMIs).

Ensure integration for efficiency and productivity.

Process Optimization:

Collaborate with technicians to optimize processes via automation.

Implement advanced control algorithms for precise parameters.

Energy Efficiency and Sustainability:

Identify energy optimization opportunities.

Implement strategies to minimize consumption.

System Integration and Upgrades:

Plan and execute integration projects.

Evaluate and recommend technology upgrades.

Safety and Compliance:

Ensure compliance with safety standards.

Implement safety interlocks and shutdown systems.

Documentation and Reporting:

Maintain accurate documentation.

Generate reports on system performance and maintenance.

Projects & achievements:

Upgrading of Singing machine panel from conventional to PLC & HMI base system and optimization of energy consumption.

Installation of GREE 35Ton VRF HVAC system for better performance and energy optimization.

Valid enhancement in operation and control panel of BOGE S50 two compressors rating of 30KW and 37KW for energy efficiency.

Installation of 70KW solar panel on grid system for energy efficiency and backup for continuous power supply to the Digital Printing Machines.

Upgrading of BRUCKNER stenter machine panel from conventional to PLC & HMI base system and optimization of energy consumption.

Implementation of the energy management system (EMS) all over the industry for energy efficiency including many techniques and proper documentation.

Allocation and writing of electrical and mechanical inventory data in the correct form in the ERP system.

Allocation and writing of all machine data including electrical and mechanical specifications in the ERP system.

Designing and implementing daily reports (energy consumption report, powerhouse inspection report, machines daily inspection report, electrical and mechanical daily maintenance report) also in the ERP system for quality assurance, asset management, and continuous improvement.

Assistant Manager Electrical

Key responsibilities:

Electrical System Design:

Design electrical systems, layouts, and specify equipment.

Calculate load requirements and ensure compliance with codes.

Equipment Selection and Installation:

Select and install motors, drives, and panels.

Ensure compliance with electrical standards during installation.

Power Distribution:

Design and maintain electrical distribution networks.

Implement energy-efficient technologies for cost reduction.

Safety Compliance:

Develop and enforce safety protocols.

Conduct regular audits to identify hazards.

Maintenance and Troubleshooting:

Develop maintenance schedules and troubleshoot issues.

Keep records of maintenance activities.

Instrumentation and Control Systems:

Design and implement control systems for machinery.

Program and maintain PLCs and HMIs.

Software Applications:

Utilize software tools for electrical design.

Team Collaboration:

Collaborate with other engineering disciplines.

Documentation and Reporting:

Maintain documentation and prepare performance reports.

Budgeting and Cost Control:

Assist in budget preparation and monitor expenses.

Projects & achievements:

Erection and commissioning of 15 Ton Steam Boiler

HMI Design and PLC Program for Steam Boiler

Erection and commissioning of Reggiani Rotary Printing Machine

HMI and PLC services for Reggiani Rotary Printing Machine

Erection and Commissioning of Airloop Ariolli Ager Machine

HMI and PLC services for Airloop Ariolli Ager Machine

Erection and commissioning of Reggiani Stenter Machine

HMI and PLC services for Reggiani Stenter Machine

ALKAN Stenter Machine panel upgrade with HMI and PLC support

Raising Machine panel upgrade with HMI and PLC support

MTO to Shift Engineer

Key Responsibilities:

Supervising the daily routine tasks and shift staff and reporting to the manager.

Prioritize safety compliance.

Assist in maintenance, repair, and troubleshooting.

Enhance energy efficiency and implement initiatives.

Collaborate with quality control.

Contribute to project planning and execution.

Maintain accurate records and documentation.

Foster collaboration with other departments.

Stay updated on electrical regulations.

Participate in training and knowledge sharing.

Assist in managing department budget.

Seek process improvement opportunities.

Prepare for emergency response.

Contribute to environmental sustainability.

Pursue professional development and mentorship

Undertake all allocated tasks and perform them in a timely and professional manner.

Ensuring equipment is in good working order to prevent disruption of activities.

Installation of fresh electrical components and fittings.

Keep a record of all stock and supplies, including the company’s electrical equipment.

Troubleshooting of machine breakdowns and providing preventive maintenance services.

Supervise electrical works when new projects are undertaken,

Troubleshooting of Inverters, PLCs, HMIs, Control Systems,

Quoting of all electrical components.

Maintenance and troubleshooting of (Flatbed Printing Machines, Soaper Machines, Rotary Printing Machines, Mercerising Machines, Stenter Machines, Calender Machines).

Trainee to Electrical Engineer

Key Responsibilities:

Supervise daily tasks and staff, reporting to the manager.

Complete tasks promptly and professionally.

Maintain equipment to prevent disruptions.

Install new electrical components.

Keep records of stock and supplies.

Troubleshoot and provide maintenance for machines.

Supervise electrical work for new projects.

Troubleshoot Inverters, PLCs, HMIs, Control Systems.

Provide quotes for electrical components.

Perform preventive and corrective maintenance on machines

Control Room Operator

Key Responsibilities:

Inspected all plant activities on screens and computers to identify and troubleshoot any issues.

Kept plant areas clean and ready for inspections to maintain high audit and compliance scores.

Tested water and condensate to check safety and compliance with regulations.

Maintenance and operations of Diesel Generators and Gas Generators.