خلاصہ

Electrical Engineer having diversified job experience with excellent communication, management skills, taking responsibility and initiative. Power/Energy business with expertise of Electrical Projects ( Solar, Gas & Diesel Engines), Planning, Execution Monitoring, and Maintenance. Possessing a proven track record of preparing and executing project plans and programs, ensuring that work is carried out in accordance with the company’s procedures and clients satisfaction within given deadlines, while complying with high standards of Quality & Safety as far as have Capability to maintain the installed equipment on international standards of with diversity of Modification. Able to ensure timely, safe and cost effective design and implementation during the life cycle of projects/ Maintenance from conception till customer satisfaction.

پراجیکٹس

تجربہ

Functional Specialist Electrical

As Senior Manager Projects, coordinate with stakeholders; finalization of scope of work, budget preparation, and approval, coordination with the Vendors and Contractors, oversee project planning & management, monitor and control the project execution works and commissioning, closing and handover the projects.

As Unit Head Engineering, liable for Maintenance of all production machines, coordination, and provision of utilities (power, steam, compressed air, RO & Raw water, etc.) and infrastructure reliability and maintenance.

• Managed the following key projects:

o EPCC for Denim Plant around 1,000,000 sqft in 10 months (1st Largest LEED Platinum Plant across the Globe)

o EPCC for New Hosiery Division comprises 800 Knitting Machines (LEED Gold Certified Plant)

o EPCC for Tights Project

o EPCC for Development and Installation of 405 Knitting Machines

o EPCC for Central Warehouse Project

o EPCC for Record Room Project

• Project Manager of New Hosiery Division, responsible for Engineering, Procurement, Construction, Commissioning and handover the facility to Production Department.

• Align sessions with all stakeholders to clarify and finalize the scope of work.

• Development of Piping Layouts, approval of the design, generation of GA / isometrics drawings, and subsequent procurement of material, fabrication, and site execution works.

• Equipment standardization, responsible for purchase of equipment as per the required specifications with efficient energy consumption.

• Project Progress review meetings with the Contractors / Vendors to monitor and control the Projects.

• Preparation of procurement plans to keep on track all long-lead items.

• Responsible for site execution works with Safety and Quality.

• Preparation and approval of the respective project budget. Monitor the consumption details and manage to complete the Project within the budgeted value.

• Commissioning, closing and handover the project to respective Client.

My core responsibilities are to plan and manage Preventive/Corrective maintenance schedules of installed equipment, maintain their history records, Inventory, Timely procurement of engineering items to keep store balance active, also make correspondence with purchase department and supplier to clarify technical specifications, searching of compatible/economical spares for the replacement of obsolete items and also monthly reports. I have profound knowledge of Electrical System Designing, Operation & Maintenance of Electrical System, in- house repairing & testing of various brand VFD’s, PLC’s (Mitsubishi PLCs FX3G60MR, Siemens S7- 200 CPU-224, OMRON PLC CM1H-CPU51, ALLAN BRADELY), (GX developer, micro win step-7, CX- One, RSLogix), HMI’s (Weintech, Kannegiesser), (Easy Pro Builder) and their intercommunication protocols. My additional expertise’s are in Project Management (MS Project Management and Primavera 6) & Execution and reported to Group Manager (E&I).

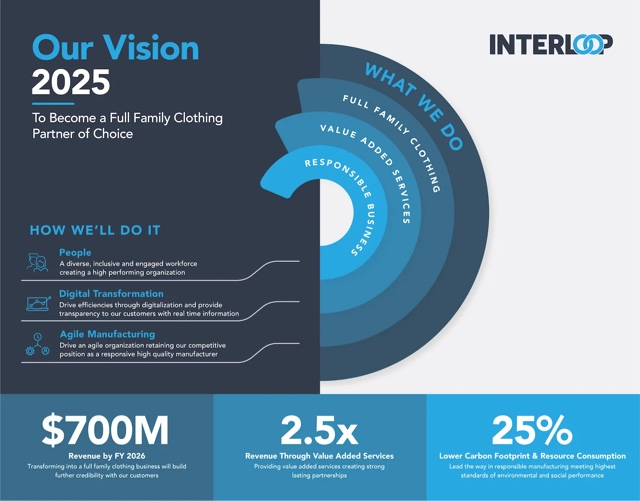

Working on Interloop Vision 2025 Full family clothing business expansion Project

including (Spinning, Apparel and Denim) in Faisalabad, I am Responsible for the timely job completion, Interactions with vendors, Electrical Design with vendors, Liaison with Govt. Teams and Approvals for the ongoing project regarding Electrical Work. Electrical Machinery and Equipment Test Run as well as a bird’s eye view on site construction work (Project in progress).

Installed a double girder Top running crane of Class D for Interloop denim project and for Power house.

Fully aware of the Use of Microsoft Project management tools and using this in the ongoing project.

Worked on the Primavera 6 project management software at beginner level in the previous project under the management.

Installed/Commissioned/Operation of 1No. YORK Centrifugal Liquid Chiller by Johnsons Controls USA, Model: YKI4KH95ESG Capacity 800Tons, 500KW. Installation of 658HP, 400V, 880A YORK OptiSpeed Drive by Johnsons Control USA Model: TM658 K B12-50D.

Assistant Manager E&I

Responsible for installations, modifications and troubleshooting at plant as per requirements.Develop, implement and review operation and routine maintenance SOPs.Responsible for plant load management and synchronization in liaison with Grid team.Responsible for troubleshooting of plant equipments in coordination with maintenance teams.Maintenance and troubleshooting of 7 x 2.0 MW, Daihatsu HFO engines and 2 x 3.0 MW J620 Gas engines.Maintenance and troubleshooting of Polymer Production Plant with 100 Tons/day capacity.Maintenance and troubleshooting of Plant Utilities including Santotherm Boilers, Air compressors, Chillers, Air Dryers, AHU (Air handling units), N2 Plant Waste Heat Recovery Boiler and Gas ignited HFO boilers.Installation, Testing, Commissioning, Operation and Maintenance of electrical equipments like Transformers, Generator, LV / MV Switchgear Breakers, NGR panel.Transformers No load test, Full load test, Impedance measurement test of power transformer, Safeties testing of power transformer, Dielectric Insulation test of transformer oil and Generator, Meggar test of LV cables, LV panels and motors.Installation, Testing, Commissioning, Operation and Maintenance of Generator Protection & Synchronization panels.

Electrical Engineer

Installation, Testing, Commissioning, Operation and Maintenance of electrical equipment’s like Transformers, Generator, LV / MV Switchgear Breakers, NGR panel, Installation, Testing, Commissioning, Operation and Maintenance of Generator Protection & Synchronization panels.

Maintenance of 5.65 MW MHI Engine along with Maiden 5.65 MW alternator.

Maintenance and check of Protection System and PLC control system of the generator.

Maintenance of VCBs, ACBs, LBS and MCC related to Generator.

Synchronization of 5.65 MW MHI Engine with WAPDA.

Responsible for load management in liaison with Grid team.

Responsible for troubleshooting in coordination with maintenance teams.

Transformers No load test, Full load test, Impedance measurement test of power transformer, Safeties testing of power transformer, Dielectric Insulation test of transformer oil.

Maintenance and troubleshooting of Plant Utilities including Boilers, Bleaching area, Air Compressors, Straw Pulp preparation, Digester area, Hydraulic Press System, Paper and board moisture Content and Sizing Scanner, Pre dryer, post dryer, Liquor preparation system, Vacuum Pump Control system, Guided Roll system and Conveying system